Expert Installation

FIBER END FACE

While it seems we can never hammer home enough the need to properly clean and inspect fiber end-faces since contamination remains the number one cause of fiber link failures, have you ever thought about what exactly you are cleaning and inspecting?

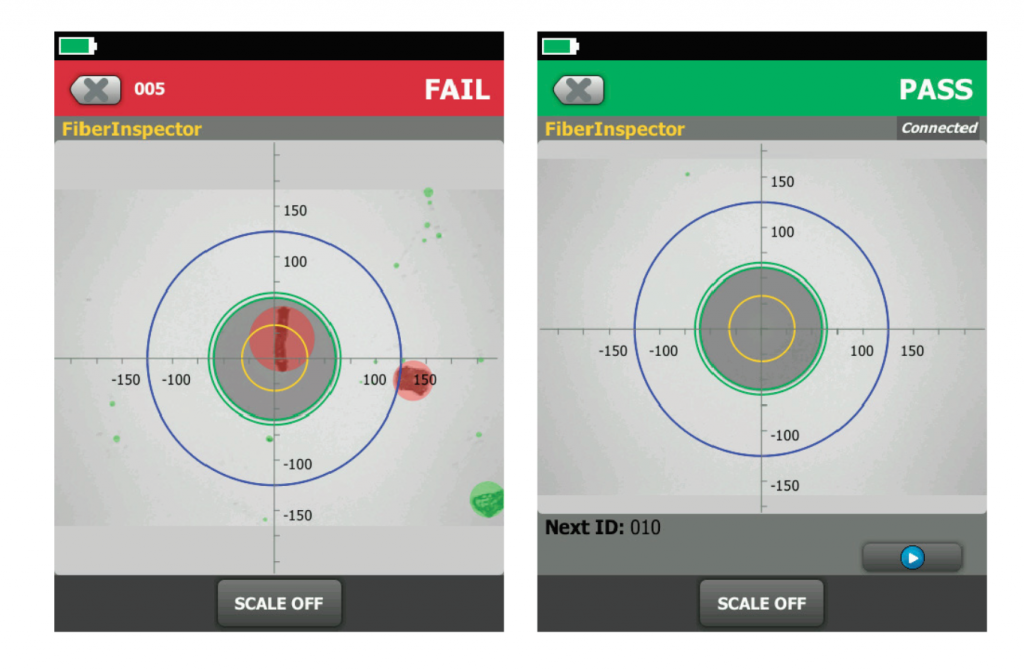

Defects on a fiber end-face come in all types, shapes and sizes. They include scratches, cracks, and pits and contaminants like dirt, dust, oil and even salt. If you properly clean a fiber end-face Fiber End Faces inspection with Fluke Networks’ FI-7000 FiberInspector Prowith lint-free wipes and a specialized solvent designed specifically for fiber cleaning, it’s possible to remove contaminants from the fiber end-face. But what about permanent surface defects like scratches, cracks and pits that can’t be removed via cleaning?

Pits typically appear as irregular shaped areas where glass has been removed due to either improper handling, poor manufacturing processes or hard debris on the fiber end-face present during mating. Cracks appear as jagged lines on the fiber end-face, and while they may resemble a scratch, they are much deeper. Pits and cracks usually mean the connector needs to be repolished or replaced. But scratches are little different. Defined as a having greater length than width, a scratch on a fiber end-face doesn’t necessarily mean it won’t pass inspection. But it doesn’t necessarily mean it will either. That’s because when it comes to scratches, it’s all about the size and location.

Fiber optic cabling must be installed in a clean, well organized environment. Small scraps of glass cleaved off the ends of the fibers being terminated or spliced can pose a hazard to installers and building occupants, and must be disposed of properly by the installer OR With fiber networks at the core of a business’s most important asset – the data center- and with the need to keep up with consumer demand for high-speed access to information anywhere and anytime, downtime and poor network performance are simply no longer an option. As network applications require more bandwidth and transmission speeds continue to climb from 1 and 10 gigabits per second (Gbps) to 40 and 100 Gbps, loss budgets have become tighter than ever. Dirt, dust and other contaminants are the enemies of these higher-speed data transmission rates over fiber networks. It is therefore critical that all optical connections be kept free of contaminations to avoid application performance issues.

With contamination being the single greatest cause of fiber failures, spending the extra few seconds to properly inspect and clean every connector end-face will save time and money in the long run.

While accidently touching a fiber end-face and working in dirty, dusty construction environments are known causes of contamination,

there are plenty of other ways to mishandle fiber that may not be obvious sources of contamination. Brushing an end-face on clothing

that can contain body oils, lint or other substances can cause contamination. In fact, any time an end-face is exposed to the surrounding

environment, it is subject to contamination – even if it was recently cleaned. Dust in the air can easily collect on a fiber end-face,

especially in the presence of static electricity.Contamination by dirt is a also a major concern for installers. The technology has become so advanced that airborne particles are roughly the size of the fiber’s core. When dirt particles contaminate fiber ends, they absorb a great deal of light and are the biggest cause of scratches on polished connectors, causing loss of fiber performance.

Axiom installers maintain clean, neat work environments to ensure their safety and the safety of building occupants. This attention to detail also ensures that all Axiom installations realize fiber’s full potential.

There are many ways to terminate fiber optic cables, each with its advantages and disadvantages. Axiom’s preferred method of termination is the method of Fusion Splicing.

Fusion splicing is the process of fusing or welding two fibers together usually by an electric arc. Fusion splicing is the most widely used method of splicing as it provides for the lowest loss and least reflectance, as well as providing the strongest and most reliable joint between two fibers.

Axiom has invested in the equipment and training needed to perform efficient and effective fusion splicing terminations for the best long term installation of your fiber investment.

Axiom has the training and equipment necessary to utilize alternate termination methods including anaerobic connectors and mechanical crimping.

- Single Mode Fiber Optic Cable

- Multi Mode Fiber Optic Cable, including 10 gig

- Aqua Fiber Optic Cable

- Needs Assessment

- Design Assistance

- Directional Boring

- Trenching and Underground Installation

- Aerial and Overhead Installation

- Precision Splicing

- Complete Testing and Verification